Ceramic Double Sided & CBN Double Sided

Features

Common problems in plane grinding include low grinding efficiency (unable to grind), short service life of grinding disc, substandard workpiece precision, workpiece scratches, poor workpiece finish and blackened surface. Based on the above common problems, our chief engineer has refined the formula, controlled the raw materials, optimized the production process and matched the scientific management system to make our products have more advantages in the market. In the grinding of the end face of the workpiece, the accuracy reaches 2 μm, the finish reaches Ra0.02, and some workpieces achieve mirror effect.

1: [Wear resistance] is 80-120 times that of ordinary grinding wheels

2: [Thermal conductivity] Good grinding thermal conductivity, no workpiece burns

3: [High precision] Grinding workpieces with high precision and good surface quality

4: [High efficiency] Sharp cutting and high efficiency

Advantages

1. High grinding efficiency. Use high-quality super-hard abrasives with reasonable abrasive particle size to improve the sharpness of the grinding disc.

2. Long service life. Make the grinding disc have reasonable hardness and stay sharp for a long time to reduce the frequency of dressing and increase the service life.

3. Good shape retention. Our company optimizes the grinding disc formula and provides workpiece grinding solutions to keep the grinding disc in a flat state for a long time to achieve the consistency requirements of workpiece accuracy.

Application and parameters

Ceramic diamond grinding discs are mainly used for grinding of hydraulic components, vane pumps, steering pumps, plunger pumps, hydraulic cycloid motors, oil pumps, nozzles, automotive engine parts, air conditioning compressor parts, carbide tools, PCD, PCBN tools, precision bearings, hydraulic parts and pneumatic components, measuring tools, crystal gems, glass, ceramics, silicon wafers, alumina and other workpieces, and grinding of two end faces.

The number of parts processed by each set of grinding discs is 500,000-1,500,000 pieces

Grit size 80-1,500#

Hardness 100HRB

Outer diameter 150-1,500mm

Aperture 30-500mm

Grinding disc accuracy, flatness, parallelism ≤0.02mm

Finished workpiece accuracy: roughness 0.1 μm-1.2 μm, flatness 0.001mm~0.004mm, parallelism ≤0.002mm, equal height ≤0.002mm

Structure:

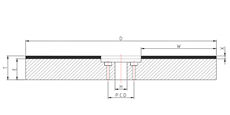

Ceramic grinding discs are made of grinding disc base and super-hard grinding blocks bonded by epoxy resin glue. The shapes of super-hard grinding discs are: round, regular hexagonal, fan-shaped, square. (Can be customized according to customer requirements).

Supporting Equipment

Double end surface grinding machines from China such as Xinxiang Scaife, Xinxiang Wanhua, Xinxiang Risheng, Wenzhou Baicheng, Suzhou Heruit, etc. Double end surface grinding machines from China such as South Korea AM, Japan Koyo, Germany Peter Walter, UK Lemart, etc.

Matching dressing wheel

Dressing wheels are used to dress diamond and CBN grinding wheels. Selecting a dressing wheel based on the different grain sizes and precisions of diamond and CBN grinding wheels makes dressing easier and saves time.

Specifications of double-sided diamond grinding discs and CBN grinding discs

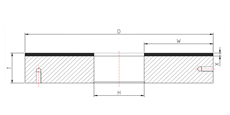

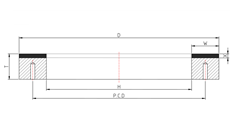

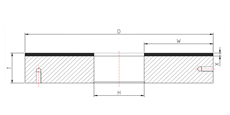

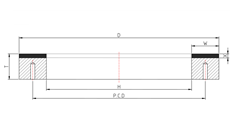

1A2T

2A2T

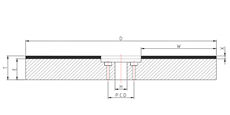

6A2B | diameter: 300mm - 1500mm |

| W(Abrasive layer width): 40mm - 350mm |

| X(Abrasive layer height): 3mm -10mm |

Parallelism: <=2μm, Flatness: <=2μm, Roughness: Ra0.02μm-Ra0.2μm Durability: Grinding and scribing (25mm*25mm), number of workpieces processed >= 1 million Carbide cutting edge, workpieces >= 1 million |

Case 1: Connecting rod surface grinding

| Workpiece material | Ductile Iron (45#, 40Cr, 40CrMo) |

| Hardness | 210-280HB |

| Grinding Allowance | Rough : 0.4 - 0.5 |

| Fine: 0.2 - 0.4 |

| Finish | Ra 0.8 |

| Size | 915* 85 * 304.8 |

| Grinding Disc Speed | 35m/s |

| No burning, no deburring required |

Case 2: Double-end grinding disc for carbide seals

| application | Double end grinding |

| Grinding wheel size | Diamond 2A2T Ø720-30T-5X-320ID |

| machine | Pitt-Volt |

| Coolant | Oil |

| Grinding wheel speed | 120 RPM |

| Workpiece speed | 30 RPM |

| Workpiece | seal |

| Material | carbide |

| hardness | 70HRC |

| Remove excess | 0,1mm total |

| Grinding rate | 70µm/min |

| Roughness | 0,20 µm Ra |

| Flatness | 0,001mm |

| Parallelism | 0,001mm |

| Abrasive particle size | 400 # |

| Grinding time | 2:30minutes |

Case 3: Double-end grinding disc for air-conditioning compressor baffle

.jpg)

Grinding results

| Thing | |

Customer | Compressor Company |

| Workpiece | Air conditioning compressor baffle |

| Workpiece hardness | HRC45-50 |

| Diameter | 90mm |

| Grinding Allowance | 0.1mm |

| Thickness | 10mm |

| Parallelism | 0.005mm |

| Flatness | 0.004mm |

| Roughness | Ra0.2 |

| Beat | 10.5s |

Case 4 Alumina Ceramic Seals

.jpg)

| Workpiece | Alumina ceramic seals |

| Workpiece size | OD22*ID17 mm*T4.5mm |

| Purity | 92% pure high alumina |

| Hardness | 1150HV |

| Remove Excess | 0.2mm |

| Number of workpieces per tray | 150 |

| Double end grinding machine model | Speedfam DSM 9B-5FH |

| Workpiece flatness after grinding | 0.001mm |

| Surface finish after grinding | Mirror |

| Grinding pressure | 150 GMs/CM2 |

| Lower plate speed | RPM70 |

| Upper plate speed | RPM 35 |

| Sun gear speed | RPM 25 |

| Cycle times | 28 times |

.jpg)

.jpg)