300-500mm Wet/Dry Concrete Diamond Blade: Flexible Cutting for All Conditions

Category: Diamond Cutting Tools | Concrete Cutting SolutionsTarget Audience: International Procurement Teams, Professional Contractors, Construction FirmsKeywords: Wet Dry Concrete Diamond Blade, 300-500mm Laser Welded Blade, High-Strength Concrete CutterUpdated: 2024

Construction sites around the world present unpredictable conditions: remote job sites lack water access for wet cutting; urban projects require dust-free operations to comply with EU/US air quality regulations; some concrete substrates (e.g., precast panels) demand precision without moisture damage. For international procurement teams, sourcing a single blade that adapts to wet and dry conditions eliminates logistical headaches, reduces costs, and ensures project continuity. Chorus’s 300-500mm Wet/Dry Concrete Diamond Blade is engineered to meet this flexibility demand—combining laser-welded durability, high-strength JSD 90 diamond segments, and global compatibility. Below, we detail why this dual-condition blade is a must-have for global construction projects, its technical advantages, and how it aligns with international procurement standards.

Why Wet/Dry Blades Are Indispensable for Global Construction

Concrete cutting rarely happens in a controlled environment. From desert highways (no water) to city skyscraper sites (strict dust rules), contractors face conflicting demands that single-condition blades can’t solve. Here’s why procurement teams prioritize wet/dry versatility:

Logistical efficiency: Sourcing one blade type instead of two reduces freight costs, storage space, and inventory management time.

Compliance with global regulations: Wet cutting meets EU EN 13236 and US OSHA dust standards (29 CFR 1926); dry cutting works for water-scarce regions (e.g., Middle East, Australia).

Reduced downtime: No need to switch blades between wet/dry tasks—saving 1-2 hours of labor per day.

Material protection: Wet cutting prevents concrete spalling; dry cutting avoids moisture damage to sensitive structures (e.g., electrical conduits in slabs).

Chorus’s 300-500mm blade solves these challenges, delivering consistent performance in both conditions while maintaining the durability required for high-abrasive concrete substrates.

Core Features & Technical Advantages

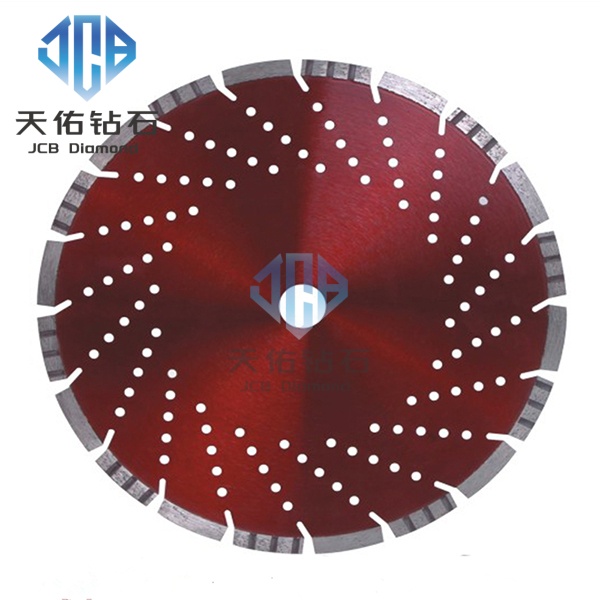

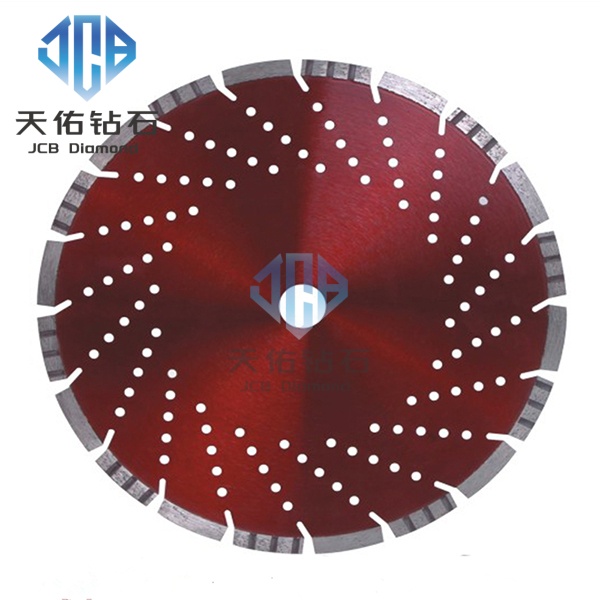

Laser Welded Bond + JSD 90 Diamond Segments

The foundation of durability and performance:

Deep metallurgical fusion: Laser welding creates a bond 3x stronger than conventional sintering, with tensile strength ≥600MPa.

JSD 90 high-grade diamond: Ensures fast cutting speed (2-5cm/min for reinforced concrete) and long service life.

Segment detachment resistance: Even in high-intensity dry cutting, the weld prevents segment loss—critical for safety and cost control.

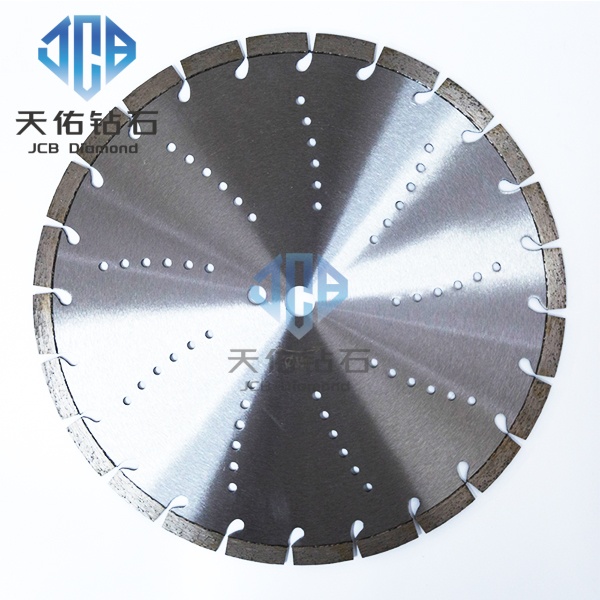

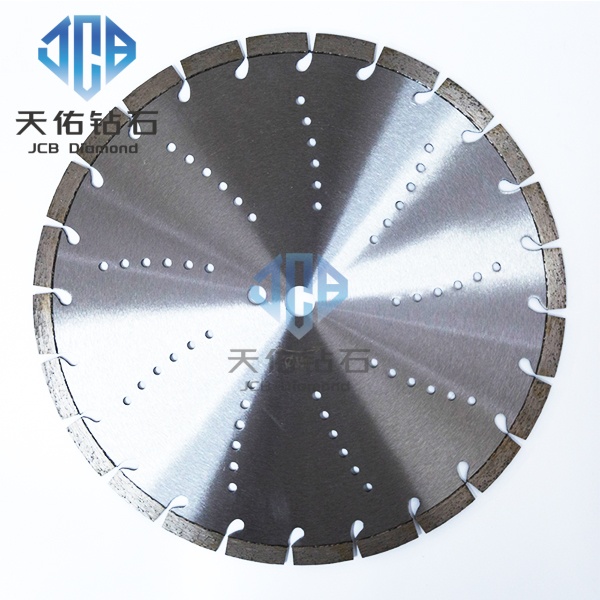

High-Tensile Steel Core (30CrMo/75Cr1 or 65Mn)

Optimized for stability in both wet and dry conditions:

30CrMo/75Cr1 option: Balances rigidity and ductility—resists warping during dry cutting’s high heat.

65Mn option: Higher hardness (HRC 45-50) for cost-effectiveness, ideal for general concrete cutting.

Water-drop groove design (wet cutting): Facilitates water flow, reducing temperature by 40% and extending blade life.

Dual-Condition Optimization

Engineered for seamless switching between wet and dry:

Reinforced notched rim: Enhances dust extraction in dry cutting; improves water circulation in wet cutting.

Heat-resistant bond: Prevents segment degradation during dry cutting’s elevated temperatures.

Smooth cutting performance: Precision-welded balance ensures vibration-free operation—critical for clean concrete edges.

Universal Compatibility + Customization

Adaptable to global equipment and project needs:

Standard 25.4mm center hole: Fits 95% of walk-behind saws (Husqvarna, STIHL, Makita) and handheld cutters.

Customizable specs: Center hole size, side/pilot holes, and body color (UV light-curing spray) available.

Size range: 300mm, 350mm, 400mm, 450mm, 500mm—covering most large-scale concrete cutting tasks.

Applications & Equipment Compatibility

Target Concrete Substrates

Concrete roads, highways, and pavement joints.

Precast cement panels, walls, and columns.

Reinforced concrete structures (beams, slabs, foundations).

General structural concrete and concrete blocks.

Compatible Cutting Equipment

Walk-behind concrete saws (15-30HP engines: Husqvarna FS 5000, STIHL TS 700).

Heavy-duty handheld cutters (16-20HP: Makita EK7651H, Bosch GDB 18V-EC).

Track saws for precision straight cuts in large slabs.

Skid-steer mounted saws for large-scale road construction.

Step-by-Step: Safe Operation for Wet & Dry Cutting

Wet Cutting Instructions

Connect a water source to the saw (flow rate: 5-10L/min) and ensure the water nozzle aligns with the blade’s cutting path.

Inspect the blade for damage; confirm the center hole fits the arbor and tighten the nut to 45-60 N·m.

Start the saw and let the blade reach full speed (2,800-4,500 RPM) before contacting concrete.

Maintain a steady feed rate—avoid forcing the blade to prevent segment damage.

Post-use: Clean the blade with water to remove concrete residue; store flat to prevent warping.

Dry Cutting Instructions

Wear PPE: N95+ respirator, safety goggles, and hearing protection (complies with OSHA/EU PPE standards).

Ensure job site ventilation or use a dust extraction system (required in EU/US urban areas).

Inspect the blade’s heat-resistant coating and segment condition—replace if warped or worn.

Operate at 10-15% lower RPM than wet cutting to reduce heat buildup; avoid continuous cutting for over 10 minutes (pause to cool).

Post-use: Remove dust with compressed air; check for segment wear (replace when height ≤3mm).

Email: [email protected]

Phone: +6616697772169

whatsapp:+852 9062 5710

Website: www.jcbdiamond.com

Address: Building 5, No.42 Qingcui South Road, Guancheng District, Zhengzhou, Henan, China